Design of In line Blender

In-Line Blending

Blending Today

Many refineries and oil terminals are still blending components using a batch blending by sequential pumping to a tank. This means, pumping sequentially “n” components from blend component tanks to a final product tank.

Why In-Line Blending?

There are many advantages in using an in-line blender vs. sequential pumping components to a blend tank; for example:

- Reduce the blending time by at least 50%, which frees tanks for other purposes and allows for less inventory on hand

- Reduce octane and vapor pressure property giveaway within the limits of error or measurements

- No off-specs or re-blends

- Minimize demurrage charges

- Fewer/less testing of blend samples (saving $)

- Direct blending to ship or pipeline to reduce tankage and inventory

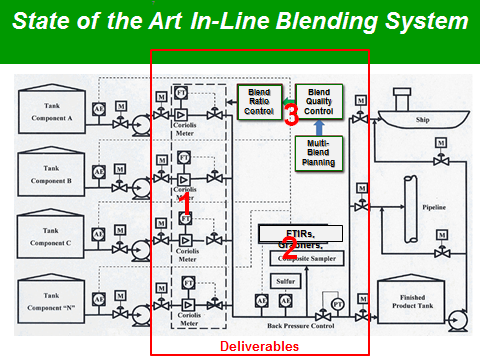

State of the Art In-Line Blending System

Refinery Automation Institute has been in the business for over 50 years, designing in-line blenders for gasoline, diesel, and bunker worldwide.

Save $-Money and switch to in-line blending. Switching to in-line blending will allow us to help you:

- Save money

- Increase tank farm throughput

- Automate and optimize the process

What We Provide

- A modular drop-In place skid-mounted, pre-wired, turn-key blender

- An analyzer shelter with pre-installed on-line analyzers

- Analyzers sampling system skids per ASTM practices

- Analyzer calibration check skids

- Blending control system using robust blend optimizer and on-line analyzer validity checking

- Installation assistance

- Blending personnel training