Crude Blending during COVID-19

COVID-19 pandemic and OPEC oil war are decimating fuel demand and cratering prices. But it will not last forever, so when the time comes, be prepared. Part of that preparation is being flexible to run any type of crude with minimum headaches.

Crude Oil

Crude oils can be stored indefinitely without degradation, particularly when the storage temperature is at or below 30 °C, and there are no seepages of hydrocarbon contaminants through the storage walls.

This is in contrast to finished transportation fuels such as gasoline which have a high content of volatile materials such as butane and natural gasoline, which evaporate easily and decrease octane. Furthermore, finished products contain olefins (chemical species) which promote the formation of gums and varnishes through oxidation reactions. The loss of octane and gums/varnishes decreases the market value of gasoline.

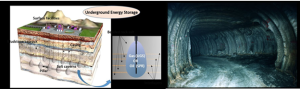

Typical SPR Salt Crude Storage

Typical Underground Concrete Crude Storage

The crude oil stored at US SPR is in salt caverns solution-mined in salt formations which provide impermeable walls and a relatively constant storage temperature of approximately 17 ° C.

Other countries also use underground storage in abandoned mines, salt rock formations, and purpose-built concrete underground storage tanks to maintain a constant temperature and minimize contamination.

Oil Degradation

Degradation of crude oil occurs when mixing “incompatible” crudes or hydrocarbons, such as highly paraffinic crude; this may precipitate asphaltenes, which will form sludge and coat the tank walls and internals of pipes and pumps. This does not render the crude unusable; it is a headache, and it just increases the cost of pumping, sludge removal, and maintenance costs.

Restoring the Quality of Crude Oil Through Blending

It is common worldwide practice for the last 50 years to blend together a multiplicity number of crude oils to economically optimize the crude feed “diet” to specific refinery requirements (in terms of yields and qualities).

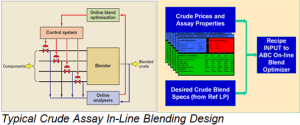

Typically, a refinery will blend 4 to 11 different crude oils in a “feed” tank or do an in-line blending of different crudes (Fig. 4). For in-line

blending, we use an on-line crude mix property analyzer (a Lab in a suitcase) installed on the blender pipe to control, precisely and automatically, the proportion of each crude oil in the mix, based on each crude property assay.